Installing Ruby in a Multiplex Funjet or Ultra

|

Overview

Here are instructions, including videos and high definition closeup pictures, for installing Ruby in the Multiplex Funjet and Ultra. For installation in other aircraft, refer to Supported Aircraft to see if specific instructions may exist. Refer to the General Installation Instructions for planes not on that list, and for more detail about some aspects of installation shown here.

The Ruby installation in the Funjet/Ultra is particularly tidy. All sensors and modules can be put into a single bundle. The only alterations you will have to make to the Funjet or Ultra are the boring of some 1/8'' diameter holes in the nose and sides of fuselage for airspeed sensor tubing. All modifications can easily be made to a Funjet that has already been completely assembled.

|

| |

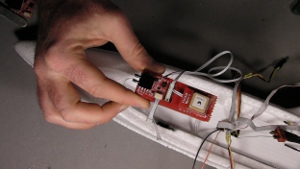

Mounting

The Ruby controller can be placed anywhere in the payload area. We find that it's easiest to balance the plane with a large battery if the controller is placed all the way forward.

The Ruby airspeed/magnetometer is required for Ruby operation.

Although it's possible to put the pitot tube in the nose and embed the airspeed sensor in the payload area, we do not recommend this because the ambient pressure inside the payload area of the Funjet is not always neutral.

We recommend embedding the airspeed/magnetometer in the wing, as is done with other planes such as the Merlin. [see airspeed/magnetometer installation instructions for the Merlin] |

click to enlarge |

You can mount the GPS unit directly on top of the controller if you prefer. You might use a little hot-glue to attach a little square of foam padding to the bottom of the GPS unit, then a little glue to attach the foam to the controller.

Note the optional "decking" made for the payload floor for extra nose strength and to keep cables out of the way. I used Coroplast (the corrugated plastic used for yard signs) cut to fit the payload floor with carbon fiber rods inserted lengthwise in the channels towards the edges. It runs all the way from the front of the payload back past leading edge of wing to strengthen Funjet at its weakest point. A hole is cut in about 4 inches from the front for cable exit. You'll probably never need to remove the cables that run under the coroplast (servo, motor power sensor, handheld receiver), but be sure not to allow allow glue on them so slack in the cabling can be freely pulled out. *** The decking is just a suggestion. It's completely optional.

|

|

that to make a "burrito" to hold Ruby in by friction.

Don't use velcro to attach the Ruby controller. Ruby's cover will tend to rip off, and velcro tends to not provide a very rigid mount.

Instead, use a small sheet of foam padding on either side of Ruby to give it a snug friction fit inside the payload area.

|

|

Clear tape holds the two sides of burrito in place. If you just did foam "U", the Ruby package might be a bit too high off the floor, keeping the canopy from fitting, especially if you put in reinforced "decking" on the payload floor as I did. |

|

When inserted, be sure that Ruby controller is flat / level / square with the payload floor / plane axes. |

|

Elevator center position raised up a bit, allowing for more upward travel which enables Ruby to fly Funjet at lower airspeeds. (Optional) |

|

| |

|

| |

|

|

Wiring the power sensor and switching regulator

Overview

Ruby currently requires a power sensor to enable it to control motor power with precision and track remaining battery capacity. You can fly Ruby without it connected, but you'll lose altitude hold, autonomous landing, and battery gauge capabilities.

We also recommend using a "Switching BEC" to power Ruby. See input power requirements.

To conserve space when installing in smaller planes, it's recommended that these parts be soldered together rather than add the bulk of additional connectors. |

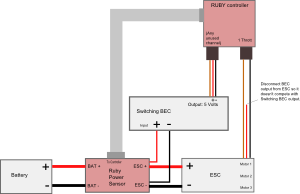

Schematic

|

click to enlarge

|

Soldering step-by-step: |

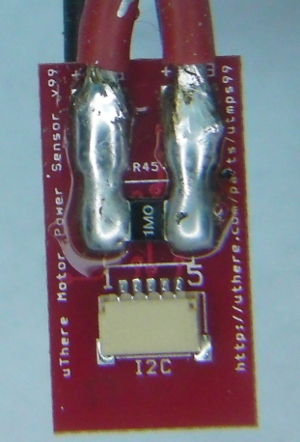

The wide copper traces through which power flows on the motor power sensor board are not sufficient to carry high current by themselves. They need a thick layer of solder on top of them to increase conductivity. Otherwise, at high power the traces can overheat and "blow" like a fuse.

Apply solder generously to cover the traces completely from the "BAT+" and "ESC+" pads all the way to each terminal of the power sense resistor. Generous solder on the power sense resistor terminals will reduce chances of it overheating and becoming inaccurate. It's ok if you get solder on top of the terminals.

|

click to enlarge |

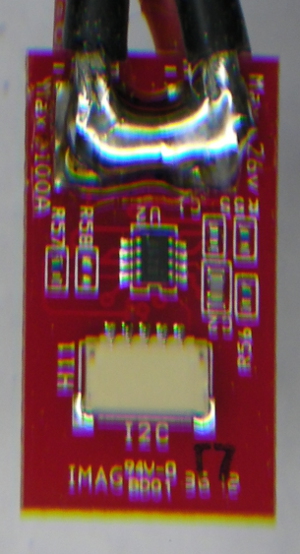

Also be sure to apply extra solder to cover the short copper trace between "BAT-" and "ESC-" on the flipside of the sensor. |

click to enlarge

|

Strip just a little bit of insulation from the end of the positve ESC power input lead and solder to the pad marked "ESC+" on the Ruby power sensor module. Solder in a position such that the uninsulated portion of the wire doesn't extend close to the edge of the board where it could short with the "ESC-" wire that will be soldered to the opposite side.

Likewise, strip and solder the negative ESC power input lead to pad marked "ESC-" the opposite side of the Ruby power sensor.

Likewise, strip and solder the pieces of wire that were cut from the ESC to the pads marked "BAT+" and "BAT -".

If a battery connector was not already attached to those wires, solder one on. Even with a small plane like the Merlin, typical motor power is 2 - 4 amps with 8 amp peaks, so we prefer larger connectors such as Dean's "T" plugs.

Solder the positive power input wire of the switching BEC in with the positive power input wire of the ESC at the "ESC+" pad on the Ruby power sensor.

Solder the negative power input wire of the switching BEC in with negative power input wire of the ESC at the "ESC-" pad on the Ruby power sensor.

*** Be sure that no uninsulated portions of wires extend beyond the edge of the Ruby power sensor. In other words, be sure that there's no way that + and - leads could possibly short if the cables are twisted in any way. |

click to enlarge |

click to enlarge |

click to enlarge |

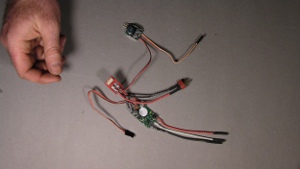

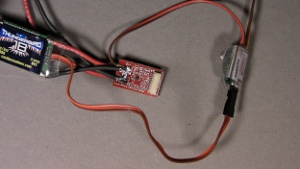

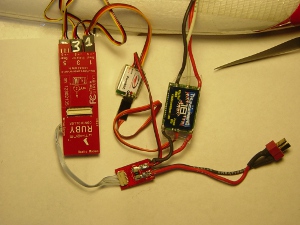

Here's what everything looks like when it's connected to Ruby,

(... except that the power sensor will be covered with electrical tape).

This picture is using a ParkBec, which combines power and throttle control into a single servo connector.

For other BECs, you'll have to plug the BEC power into an unused channel on Ruby separate from the throttle, or use a standard servo "Y" cable so the BEC can share a port with throttle or other servo. Be sure to disconnect the power wire coming in on the Throttle connector from the ESC so that the ESC's BEC and switching BEC are not trying to power the same electronics. |

click to enlarge |

Cover all exposed metal contacts.

Wrap the power sensor in electrical tape or heat shrink tubing. For easier packing, tape the power sensor to the ESC to form a single bundle. Don't wrap tape around the ESC to the extent that it becomes thermally insulated and more susceptible to overheating. |

Keep switching BEC away from GPS and R/C receivers.

In our testing, we've found that the typical BEC needs to be at least 3 inches from GPS and R/C receiver.

Note: The latest version of the motor power sensor connects to the connector labeled "I2C1" on the Ruby Controller. (Don't confuse with "I2C2" on the Expander.). The port labeled "Motor Sense" on the Ruby Controller is no longer used.

There are two connector labeled "I2C" on the power sensor. Either one can be used. The extra connector allows other I2C devices such as the airspeed/magnetometer to be daisy-chained.

|

Connecting the Ruby controller

The Controller will be inserted into the payload area with the servo pins facing aft, and large "RUBY" lettering facing down.

Servo connectors:

| Connect: |

to Ruby: |

Throttle

(and BEC if Parkbec) |

"1 Throt" |

BEC if not ParkBec

Empty otherwise |

"5 Gear" |

| Right Elevon |

"2 Ail R" |

| Left Elevon |

"6 Ail L" |

All servo connectors on the controller (but not the Expander) are connected to the same 5 volt / ground power bus.

If you don't have a Parkzone BEC that feeds power through the throttle servo connector, you can plug it into channel 5 "gear", which is otherwise unused.

Be sure to plug servos and BEC into Ruby with correct polarity. Plugging the BEC in with polarity reversed could destroy your Ruby! Black wires should match with "-" printed on Ruby cover for every channel.

Ribbon cable connectors:

The ribbon cables currently don't have any markings on them, but you can identify them simply by counting the number of wires.

Motor power sensor

New version: 5 wire ribbon cable, connects to "I2C1" on Ruby Controller (not "I2C2" on Expander. "Motor Sense" connector is unused).

Old version: 8 wire ribbon cable, connects to "Motor Sense" on Ruby controller.

GPS (4 wire ribbon cable - there are two such cables in your kit. Choose whichever is the most suitable length)

Airspeed (5 wire ribbon cable).

Receiver (7 to 9 wire cable, depending on adapter, with a partially populated 12 wire connector that plugs into Ruby)

The "USB Dongle" and cable is just intended for temporary use on the bench. You can omit it here.

|

| |

Balance

Follow manufacturer's directions regarding balance of the plane.

Proper balance is critical for any aircraft, whether or not a system like Ruby is in place to offer artificial stabilization. Although Ruby's "fly by wire" capability may (or may not) be able to bring an unstable plane under control, it will still fly very poorly without radical changes of settings away from standard default values, and excessive servo activity. Most notably, if the plane is a little tail heavy, Ruby control of pitch and airspeed will be erratic with standard settings, and if it's too tail heavy, the plane will be completely uncontrollable with any settings. |

|

Configuration

Now that Ruby is physically installed, you'll need to load configuration settings to match your airframe, receiver, and preferences.

Please proceed to configuration.

|

|